Technology

When people learn about how simple and elegant the Smart Thruster is, they often ask,"why didn't some one think of that before?" The truth is, the enabling technologies have only recently become available.

One of the key enabling technologies are the LiFePo4 batteries. These have only been readily available within the last few years. They are unique in their ability to provide a large amount of power in a compact and light weight form factor. A bow thruster requires a large amount of power over a relatively short period of time. The SmartThruster can operate continuously for about 10 minutes before needing to be recharged. Of course, A typical docking requires less than a minute of operation. Recharging from the fully depleted state takes about 3 hours and only 90 minutes if charged at the recommended 50% or more state.

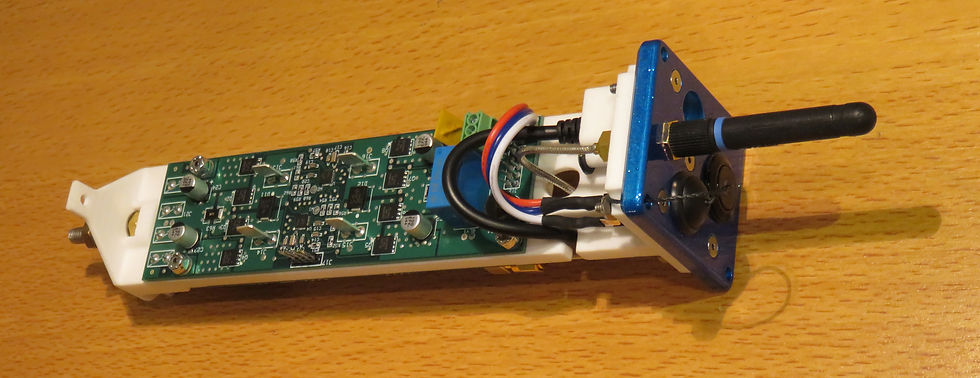

Another challenge with the thruster's high power requirement is switching the high-current to the motors. Modern motor controllers use Field Effect Transistors (FETs), but these need to dissipate a lot of heat when switching high current. Fortunately, recent developments in FETs and FET controllers by Texas Instruments enable more efficient switching. This eliminates over-heating and insures long life.

Advanced batteries such as the LiFePo4 batteries require sophisticated charging algorithms and over/under voltage monitoring. Fortunately, modern microcomputers like the one used in the Smart Thruster are small and can readily manage the monitoring and control functions of charging and discharging the battery efficiently and safely. The microcomputer also manages the radio interface and the soft start and stop of the motors, reducing the motor jerking and improving their life.

The radio transmitter and receiver are made by Linx Technologies located in Oregon. They use the latest radio technology, are certified to FCC standards, and have very good performance.

The electronic circuit boards are fabricated in Oregon by ExpressPCB, a leading West Coast circuit board fabricater. The assembly of these circuit boards is done by PCA Corp. in their modern Bellevue, Wa. facility.

Even the plastic and metal parts are the latest technology. The plastic parts are 3-D printed by Shapeways in New York using an advanced laser-sintering process to make the various nylon parts. The metal parts are fabricated in New Jersey by "e-machine shop" in their state-of-the-art fabrication facility. Their faceplate is finished in a modern metallic-blue powder coat.

The DockStar Smart Thruster combines all these technologies together to make a high-quality device compact and light enough to be easily mounted to the outside of the hull.